Quarry Project: A Case Study

Better Inventory Planning Through Drone Volumetric Analysis

The marvel about using a drone to capture imagery is the extremely high quality that can be captured compared to other methods.

It is important for quarry operators to keep track of their inventory in order to know:

1

Amount

How much rock they have in each stockpile.

2

Type

How much of each rock type and rock size they have.

3

Orders

How many orders they can fill with each pile.

4

Blasting

How often they will have to do blasting operations to create more inventory.

To keep track of inventory many quarry operators use traditional survey methods such as walking the quarry property collecting GPS data going up and down stockpiles ,or by doing estimations of the quantity of rock based on visual inspections. Larger quarries have also used LIDAR data received from flyovers, however the cost of this often outweighs the benefits for many quarry operators.

Traditional survey methods can be both costly and time consuming. With the introduction of drone technology the same insight can be provided at a lower cost, making it far more beneficial to a quarry operator.

Using a drone to capture the data allows the quarry operator to receive information on stockpiles for planning purposes. The high quality bird’s eye view of the entire property can provide insight into potential future blasting sites.

Background

This project was completed using a medium sized limestone quarry located in the Grey County region of Ontario. The quarry is an active operation site and thus any shut down to allow surveying would be costly to the operator. The quarry operator needed something unobtrusive to conduct surveys to prevent shut downs.

The quarry operator’s highest priority was to determine how much rock was available in the stockpiles in order to match inventory to current and future orders.

The Flight

For this project, a Mavic 2 Pro was used to conduct the flight over the quarry. The total flight area covered approximately 50 acres of land, which included the active quarry site and some of the surrounding land where expansions for rock excavation could occur.

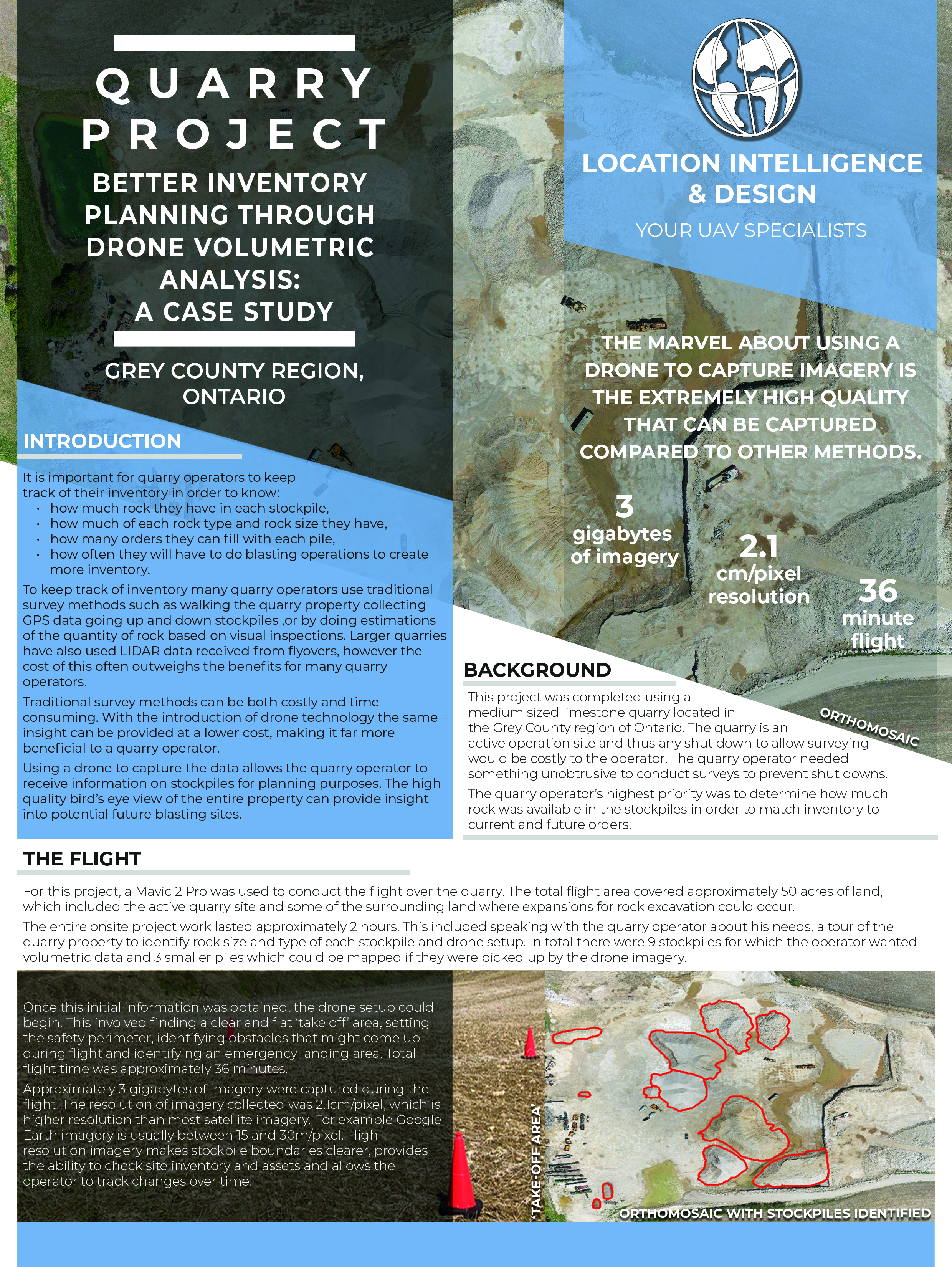

The entire onsite project work lasted approximately 2 hours. This included speaking with the quarry operator about his needs, a tour of the quarry property to identify rock size and type of each stockpile and drone setup. In total there were 9 stockpiles for which the operator wanted volumetric data and 3 smaller piles which could be mapped if they were picked up by the drone imagery.

2.1

Resolution

2.1 cm/pixel

3

Gigabytes

277 photos

36

Flight Time

1.5 Batteries on Mavic 2 Pro

Pre-flight

Once this initial information was obtained, the drone setup could begin. This involved finding a clear and flat ‘take off’ area, setting the safety perimeter, identifying obstacles that might come up during flight and identifying an emergency landing area. Total flight time was approximately 36 minutes.

Approximately 3 gigabytes of imagery were captured during the flight. The resolution of imagery collected was 2.1cm/pixel, which is higher resolution than most satellite imagery. For example Google Earth imagery is usually between 15 and 30m/pixel. High resolution imagery makes stockpile boundaries clearer, provides the ability to check site inventory and assets and allows the operator to track changes over time.

What do you do with all that data?

Using the drone to collect the data is the easy part! Knowing what to do with it requires detailed skill and knowledge. Processing and understanding the data becomes complex when dealing with large datasets.

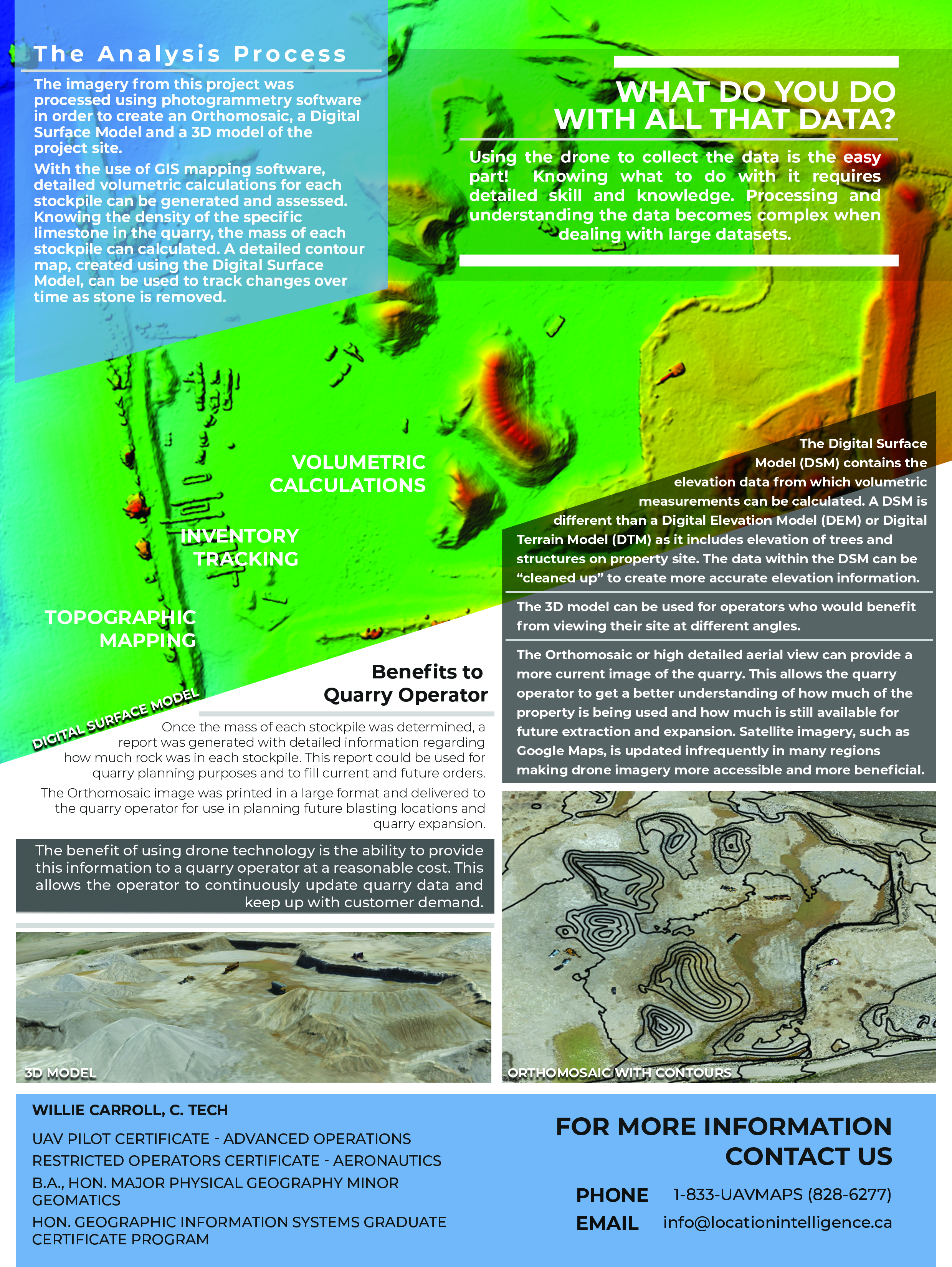

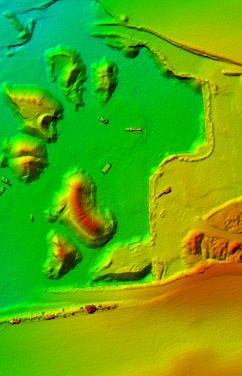

The imagery from this project was processed using photogrammetry software in order to create an Orthomosaic, a Digital Surface Model and a 3D model of the project site.

The Analysis Process:

With the use of GIS mapping software, detailed volumetric calculations for each stockpile can be generated and assessed. Knowing the density of the specific limestone in the quarry, the mass of each stockpile can calculated. A detailed contour map, created using the Digital Surface Model, can be used to track changes over time as stone is removed.

Topographic Mapping

Quarry Inventory Tracking

Volumetric Calculations

Orthomosaic

The Orthomosaic or high detailed aerial view can provide a more current image of the quarry. This allows the quarry operator to get a better understanding of how much of the property is being used and how much is still available for future extraction and expansion. Satellite imagery, such as Google Maps, is updated infrequently in many regions making drone imagery more accessible and more beneficial.

Digital Surface Model

The Digital Surface Model (DSM) contains the elevation data from which volumetric measurements can be calculated. A DSM is different than a Digital Elevation Model (DEM) or Digital Terrain Model (DTM) as it includes elevation of trees and structures on property site. The data within the DSM can be “cleaned up” to create more accurate elevation information.

Benefits to Quarry Operator

Once the mass of each stockpile was determined, a report was generated with detailed information regarding how much rock was in each sttockpile. This report could be used for quarry planning purposes and to fill current and future orders. The Orthomosaic image was printed in a large format and delivered to the quarry operator for use in planning future blasting locations and quarry expansion.

The benefit of using drone technology is the ability to provide this information to a quarry operator at a reasonable cost. This allows the operator to continuously update quarry data and keep up with customer demand.